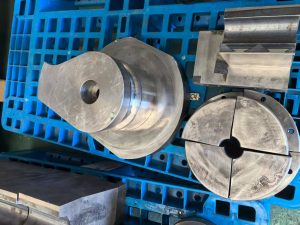

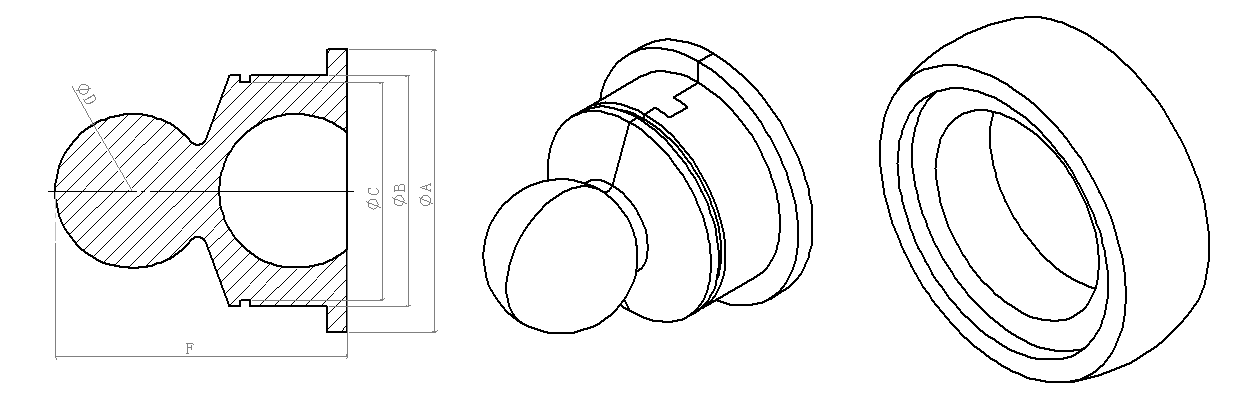

Mandrel

|

|

|||||||

| NO. | A | B | C | D | E | F | Inner diameter of steel pipe |

| 2# | 12 | 10 | 9.6 | 7.35 | 1 | 15.3 | Φ15.875-Φ22.225 |

| 3# | 14.3 | 12 | 11.2 | 9.5 | 1.1 | 19.6 | Φ22.225-Φ28.575 |

| 4# | 18.5 | 16 | 15.2 | 12.7 | 1.1 | 25.9 | Φ28.575-Φ34.925 |

| 5# | 21.6 | 19 | 18 | 16 | 1.2 | 31 | Φ34.925-Φ41.275 |

| 6# | 25 | 22.2 | 21 | 19 | 1.35 | 35.7 | Φ41.275-Φ47.625 |

| 7# | 31 | 26.2 | 24.9 | 22.2 | 1.75 | 42 | Φ47.625-Φ53.975 |

| 8# | 34 | 30 | 28.6 | 25.4 | 1.75 | 48.5 | Φ53.975-Φ60.325 |

| 9# | 40 | 34.8 | 33.2 | 28.5 | 1.75 | 54.8 | Φ60.325-Φ66.675 |

| 10# | 47 | 40 | 38 | 31.75 | 1.95 | 59.5 | Φ66.675-Φ72.725 |

| 11# | 56 | 48 | 45.5 | 38.1 | 1.95 | 72.4 | Φ79.375-Φ98.425 |

| 12# | 62 | 52 | 49 | 44.4 | 2.2 | 84.3 | Φ98.425-Φ117.475 |

1. Use a mandrel for bending thin-walled tubes;

2. Use a mandrel when the bending radius is small;

3. Customizable special-shaped mandrels, such as rectangular, oval, U-shaped, etc;

4. It is recommended to use a universal mandrel for the CNC angle pipe bending machine;

5. The universal ball is made of 42CrMo alloy steel and undergoes heat treatment;

6. The ball cover can be customized with materials such as brass and 42CrMo;

7. For detailed parameters, please consult our company and inform us of the pipe diameter, wall thickness, material, and bending radius.

Dies